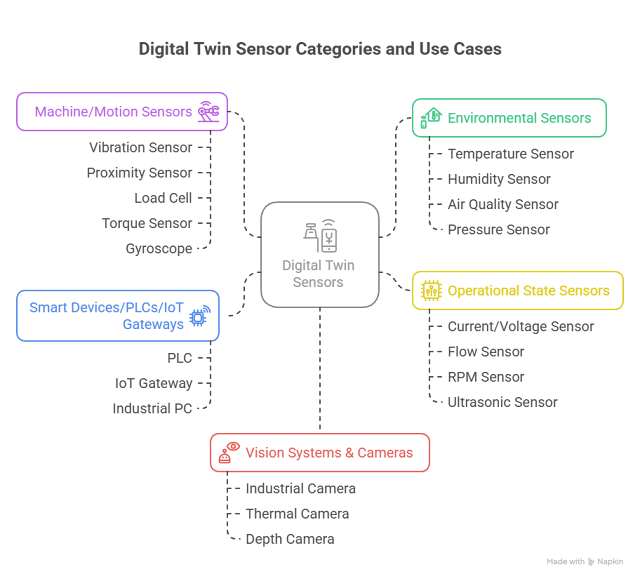

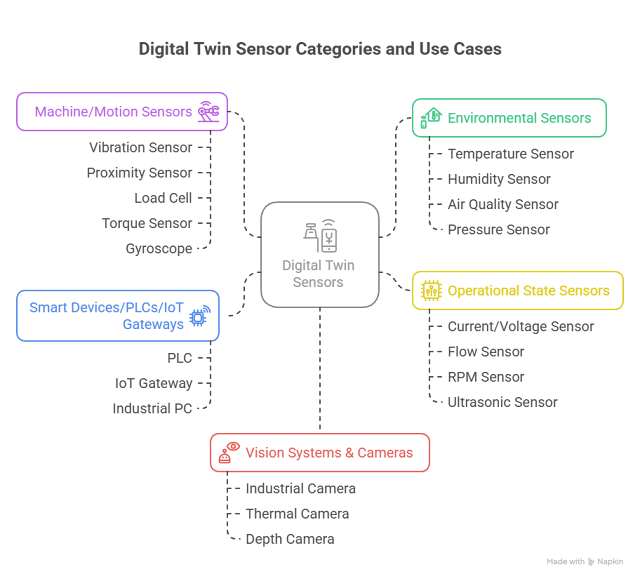

The quality and type of physical devices/sensors determine the richness and usefulness of your Digital twin. Physical Devices or Sensors vary based on industry and use case, but here are the most common categories, with examples and use cases:

🔧 1. Environmental Sensors

These track the ambient conditions around the equipment or area.

| Sensor Type | Measures | Example Use Case |

|---|

| Temperature Sensor | Heat levels | Monitor motor heat to prevent overheating |

| Humidity Sensor | Moisture in air | Used in food packing or pharma industry |

| Air Quality Sensor | CO2, VOCs, PM2.5 | Monitor air quality in manufacturing plants |

| Pressure Sensor | Atmospheric/gas pressure | Used in pipelines or tank systems |

|

| Digital Twin Sensors |

⚙️ 2. Machine/Motion Sensors

These are attached directly to machines and moving parts.

| Sensor Type | Measures | Example Use Case |

|---|

| Vibration Sensor (Accelerometer) | Mechanical vibration | Detect misalignment or wear in motors |

| Proximity Sensor | Object presence/distance | Detect box on conveyor belt |

| Load Cell | Weight | Verify item is packed correctly |

| Torque Sensor | Rotational force | Measure robotic joint load |

| Gyroscope | Orientation/tilt | For robotic arms or mobile robots |

🛠️ 3. Operational State Sensors

Used for tracking machine health and performance.

| Sensor Type | Measures | Example Use Case |

|---|

| Current/Voltage Sensor | Power usage | Monitor energy usage per machine |

| Flow Sensor | Liquid/gas flow | Used in chemical or food processing |

| RPM Sensor | Rotational speed | Measure conveyor or motor speed |

| Ultrasonic Sensor | Distance, level | Check box fill level or tank volume |

🧠 4. Smart Devices / PLCs / IoT Gateways

These aggregate sensor data, sometimes run edge logic, and communicate with the cloud or local systems.

| Device Type | Role | Example Use Case |

|---|

| PLC (Programmable Logic Controller) | Automate machine logic | Control conveyor and capture sensor input |

| IoT Gateway (Raspberry Pi, Siemens IOT2040) | Collect and transmit data | Convert analog sensor to digital + send via MQTT |

| Industrial PC | Edge computing + visualization | Run local dashboard and control logic |

📸 5. Vision Systems & Cameras

Used for quality checks, tracking, and AI-based decision-making.

| Device Type | Measures | Example Use Case |

|---|

| Industrial Camera | Object detection, size, count | Count boxes or detect if package is missing item |

| Thermal Camera | Heat patterns | Detect overheating or insulation faults |

| Depth Camera (e.g. RealSense, Kinect) | 3D shape/position | For object detection or pick-and-place in robotics |

🧩 Real-World Example: Digital Twin of a Packing Line (Assembly Line)

| Station | Physical Devices Used |

|---|

| Conveyor Belt | Proximity sensor (box detection), RPM sensor (speed), load cell (weight) |

| Robot Arm | Torque sensors, gyroscopes, encoders (joint angles) |

| Packing Station | Vision camera (check item presence), barcode scanner |

| Environment | Temperature & humidity sensors (for product safety) |

| Edge Gateway | Raspberry Pi collecting all data and pushing to Unity/Cloud |

🎯 Summary Table:

| Category | Examples |

|---|

| Environmental | Temperature, Humidity, Air Quality |

| Mechanical | Vibration, Proximity, Torque, Load Cell |

| Electrical | Current, Voltage, Power |

| Optical | Vision systems, Barcode scanners, Depth cameras |

| Smart Devices | PLCs, IoT Gateways, Industrial PCs |

.png)

0 Comments